Types of sharpening hairdressing scissors

Hair cutting scissors have undergone a long evolution from simply pieces of metal fastened together to complex and technological tools, the manufacture of which requires the labor of several dozen specialists and the use of high-precision equipment.

Professional hairdressing scissors ROO Professional have collected the most demanded characteristics of modern cutting scissors, including such important as the sharpness and wear resistance of the blades.

What is "sharpening" and what does it depend on?

Sharpening is the grinding of two surfaces at a certain angle to obtain an edge with the desired degree of sharpness. The cutting properties of scissors depend on the angle of sharpening. The ideal shears for cutting require a high degree of sharpness that would last for a long time. But the fulfillment of this condition is possible when choosing high-quality steel for the manufacture of scissors, the stronger it is, the sharper they can be made, but, accordingly, the more expensive they will be.

What types of sharpening hairdressing scissors exist?

Among all manufacturers of professional shearing scissors, only 3 main types of sharpening are used. Each of these types of sharpening requires the manufacturer to use certain technologies, different in complexity and cost of use. These are the following types:

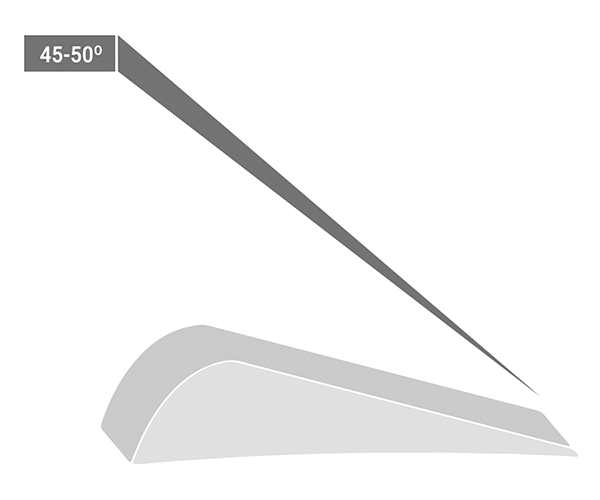

► "conventional" or "standard" — technologically the simplest type of sharpening, which is rarely used even in affordable scissors. The cutting edge on such scissors is approximately 45 - 50 degrees.

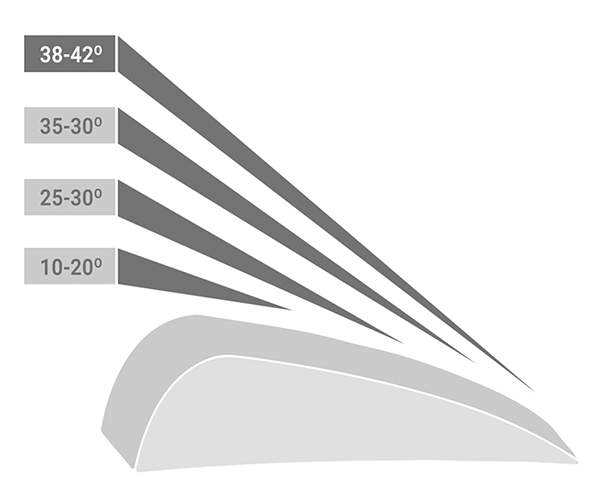

► "semi-convex" — an intermediate type of sharpening, which is a transitional type from "standard" to "convex". In them, the cutting edge is already in the range of 42-45 degrees.

► "convex" — now the most technologically complex type of sharpening. It is used in higher grade scissors, as it requires sophisticated equipment for manufacturing. The cutting edge is the sharpest, as it is formed at an angle of 38-42 degrees.

Some manufacturers produce models of scissors with "convex" sharpening at an angle of 35 degrees. But to keep such a cutting edge for a long time, the use of strong and expensive steel is required.

What are the different types of scissor sharpening?

Sharpening scissors is not just a technical parameter of the tool. It directly affects the ability to apply this or that haircut technique. The following briefly describes the possibilities with one or another type of sharpening scissors:

► scissors with "standard" sharpening — suitable for straight cuts and shading. It is impossible to perform a sliding cut with them, because due to the small angle of sharpening, the cutting edge will catch and tear the hair.

Sometimes, micro-notches are made on the cutting edge of such scissors, which prevent the hair from slipping out when the cloths are closed.

► with "semi-convex" — allows you to perform both a straight cut and a sliding one at a satisfactory level. This makes scissors with this type of sharpening quite a good option for learning different cutting techniques.

► with "convex" sharpening — the most modern and complex. Such scissors can easily perform both an accurate straight cut and the lightest slicing.

What types of sharpening are available in ROO Professional hairdressing scissors?

The range of ROO Professional hairdressing scissors includes professional models with the most functional types of sharpening.

► "semi-convex" in scissors of the initial line Star*.

► "convex" in medium and high line scissors Cobalt**, Arkansas***, Zen**** and Barber****.

You can get acquainted with the models of professional scissors ROO Professional in our catalog.